TDS: Polyvinylidene Fluoride (PVDF)

Make informed choices using our technical data insights.

TECHNICAL DATA SHEET: KEY CHARACTERISTICS AND APPLICATIONS

Polyvinylidene Fluoride (PVDF)

General Information:

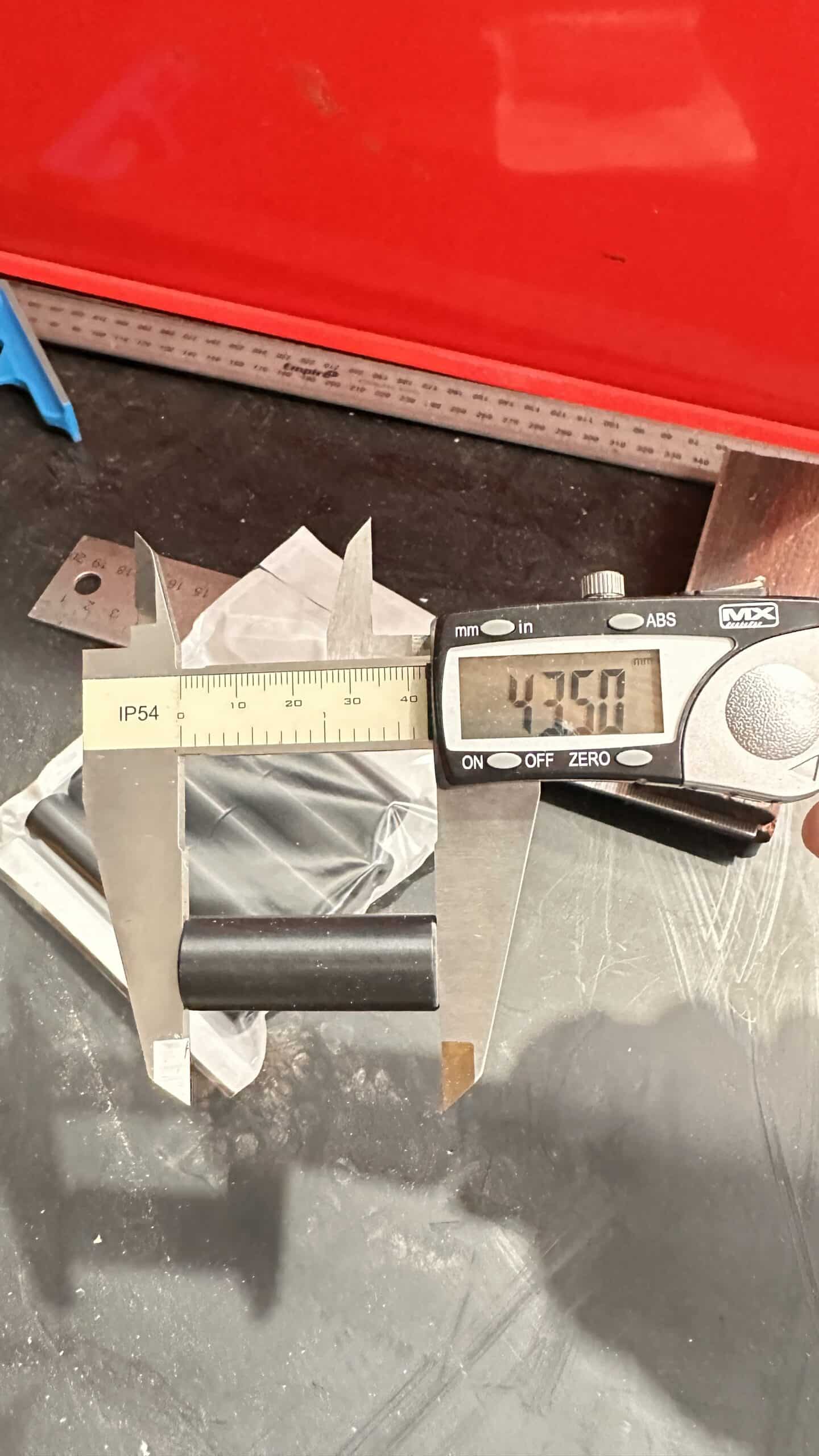

- Product Name: Polyvinylidene Fluoride (PVDF)

- Classification: Semi-crystalline thermoplastic

- Chemical Structure: Linear polymer composed of alternating vinylidene and fluoride units

Typical Properties:

- Density: 1.75 – 1.78 g/cm³

- Tensile Strength: 35 – 50 MPa

- Elongation at Break: 20 – 300%

- Tensile Modulus: 1.5 – 2.5 GPa

- Hardness: Shore D 75-85

- Melting Temperature: 165 – 175°C (329 – 347°F)

- Continuous Use Temperature: -40°C to 150°C (-40°F to 302°F)

- Flammability: V-0 (UL 94)

- Dielectric Constant (1kHz): 8 – 9

Features and Benefits:

- Chemical Resistance: Exceptional resistance to a broad spectrum of chemicals and solvents.

- UV Resistance: Excellent resistance to UV and other radiation.

- High Purity: Low ion and metal content makes it suitable for critical applications.

- Weather Resistance: Maintains properties and appearance under prolonged environmental exposure.

- Electrical Properties: Good insulator with a stable dielectric constant.

Applications:

- Chemical Processing: Piping, tanks, and valves due to its chemical resistance.

- Electronics: Wire insulation, printed circuit boards, and membranes.

- Medical: Catheters and other medical devices.

- Oil & Gas: Linings and coatings for steel pipes, and tubing.

- Building & Construction: Architectural coatings and membranes for roofing.

- Automotive & Transportation: Fuel system components and exterior parts.

Processing Methods:

- Injection Moulding: Used for the production of detailed components.

- Extrusion: Suitable for pipes, films, and sheets.

- Blow Moulding: For containers and hollow components.

- Welding: PVDF can be effectively welded using various techniques.

Environmental Impact and Recycling:

- PVDF can be recycled, but specialised processes are required due to its chemical stability.

- Post-industrial waste can be reprocessed, but high levels of post-consumer recycling are less common.

Storage and Handling:

- Store PVDF in a cool, dry environment. It is stable under typical storage conditions.

- Ensure adequate ventilation when processing to prevent inhalation of fumes.

Safety Information:

- PVDF is inert and safe to handle in its polymer form.

- During processing, fumes can be generated and should not be inhaled. Ensure proper ventilation and use appropriate personal protective equipment.

Note: This technical data sheet provides a general overview and typical properties of PVDF. Real specifications might differ depending on the manufacturer and specific product grade. For accurate details on a particular product, always refer to the manufacturer’s data sheets.

Disclaimer: The presented information is provided “as is” without warranties. Users should conduct their evaluations and tests for specific applications.